Steel detailing is a production process that translates a completed design into standard industry language that a fabrication shop understands. This translation is presented on shop drawings. See the example below.

IS IT DESIGN?

NO. Design is performed by a professional architect or engineer licensed by the state the work is performed in. In the Commonwealth of Massachusetts, it is illegal to perform architectural design work or structural engineering without a license. Reference: MA General Laws Title XVI Chapter 112, Sections 81T and 60k.

THE STEEL CONSTRUCTION PROCESS (SIMPLIFIED)

ARCH/STRUCT DESIGN (BY OTHERS) >> SHOP DRAWING PRODUCTION >> FABRICATION >> DELIVERY >> STEEL ERECTION

Each step of the process produces documents for different purposes. Here’s a look at a stair, produced by each discipline.

ARCHITECTURAL DESIGN

The architect designs a building or structure to suit the client’s needs, in accordance with applicable codes and standards. This is the initial creative step that defines what the building looks like, what systems will go into it, what materials will be used, what color the paint is, etc. Any changes made to this original concept are directed and approved by the architect.

The purpose of the drawing at right is to provide general information about that particular area of the building. There are notes about lighting, paint, and a metal stair with guardrail and a wood handrail.

There isn’t enough information shown to actually build a stair from this drawing. The “How do you build that?” questions are answered by others with more specific knowledge, and then approved by the architect.

STRUCTURAL DESIGN

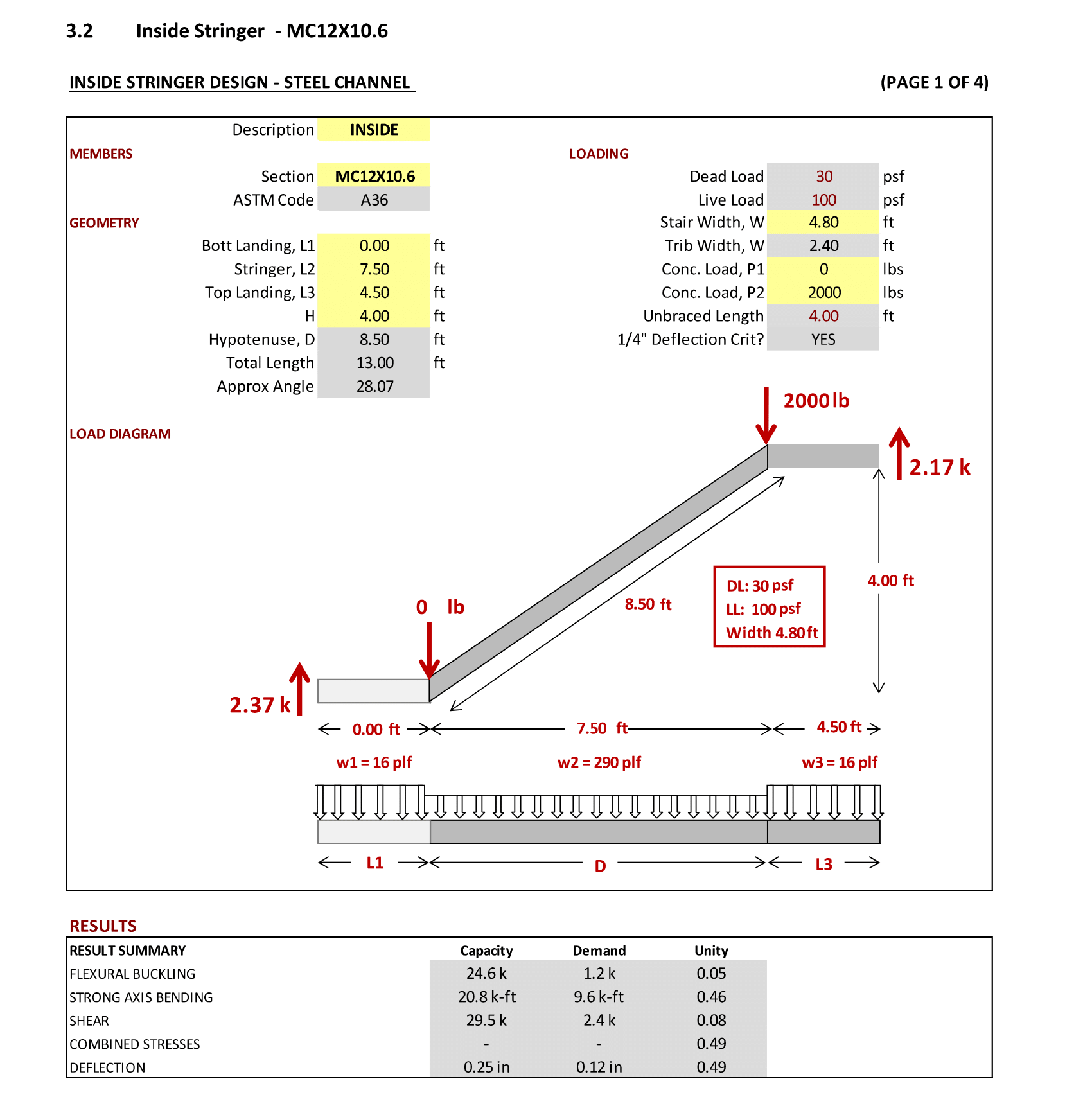

Structural engineering uses math and physics to determine what framing will support the loads created by the architect’s conceptual design.

This is the step that creates the “skeleton” of a building or structure, and specifies the parameters for how something gets built and what it is built from.

All the technical details are covered in the calculations: what size beams, what size bolts, weld requirements, the spacing of handrail brackets, connection details and more.

Calculations contain most of the information the shop uses. However, they are not formatted for that specific purpose, so the information isn’t quickly accessible for a worker in the shop.

STEEL DETAILING

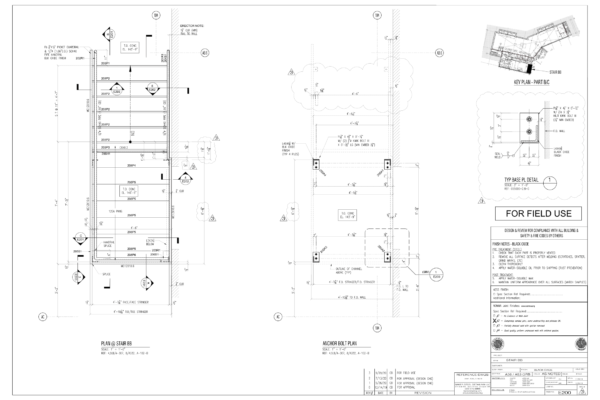

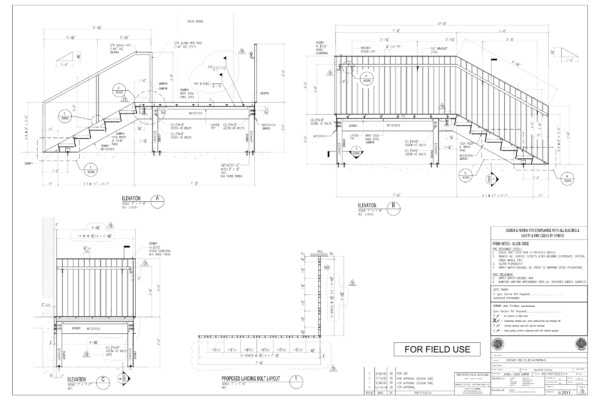

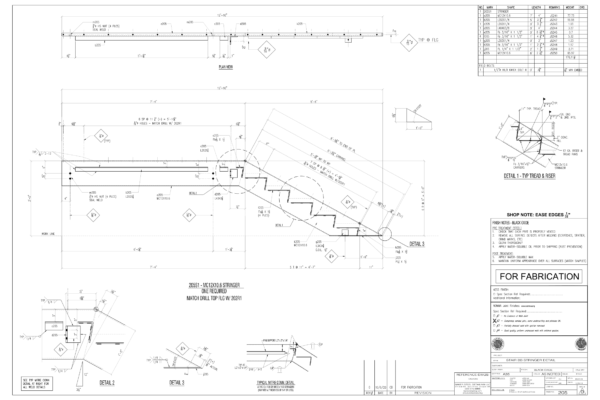

Steel detailing takes information from both the architectural design and the structural design (and often, field surveys) and combines everything into a set of drawings that can be used by both the fabrication shop and the erection crew on site.

Shop drawings present design information in a format that can be quickly read and understood by the person responsible for making a part, or installing a part. There are standard symbols and language used, as well as standard views that each fabricator expects to see. Each piece detail looks just like the finished material will look.

Notice the amount of specific information (detail!) shown on these drawings. Each part gets drawn and every bolt gets counted.

Erection Plans

- Used by the field crew.

- These drawings locate where all the large parts go and shows how they attach to each other

Piece Details

- Used by the shop.

- Drawings of each main part.

- Lengths, holes, welds and paint finish are all shown.